Exhibits regarding the mining industry and minerals found in the Queen Mine are displayed here. After buying our tickets we checked out the exhibits, gift shop, and obtained some information from the Visitor Center.

Mining equipment is displayed outside the building. These ore cars were used to bring the ore out of the mine. The larger car could haul 3 tons and the smaller (second one) 2 tons of ore.

This battery-operated train is how miners were transported into and out of the mine. And this is what we rode during the tour.

We were outfitted with a hard hat, miners lamp, yellow slicker, and belt. Also, everyone was issued a metal identification tag. This same method was used for miners entering the mines each day. Upon exiting the mine, the tags are turned in thereby assuring that no one was left behind.

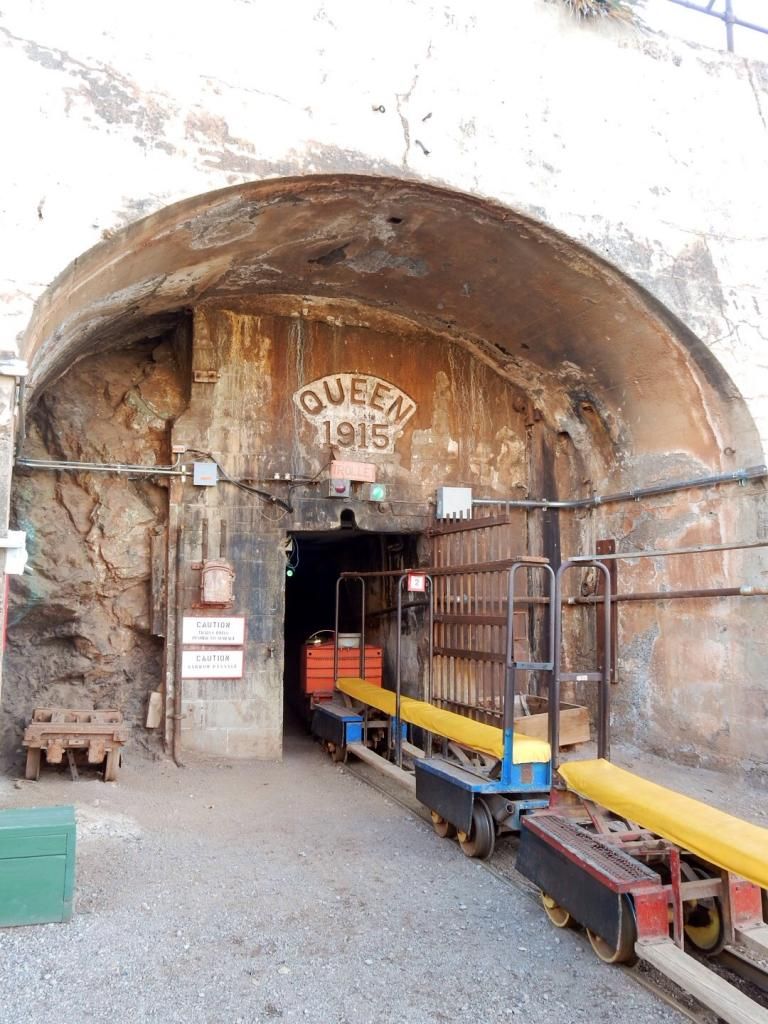

It is a constant 47 F in the mine. We travelled 1,500' into the mine (it's 3,400' deep) with several stops along the way where we got off the train to explore side tunnels. The is the entry tunnel, built in 1915.

The tunnel...it was nice having miners lamps so we could look around as we traveled through this narrow, dark space!

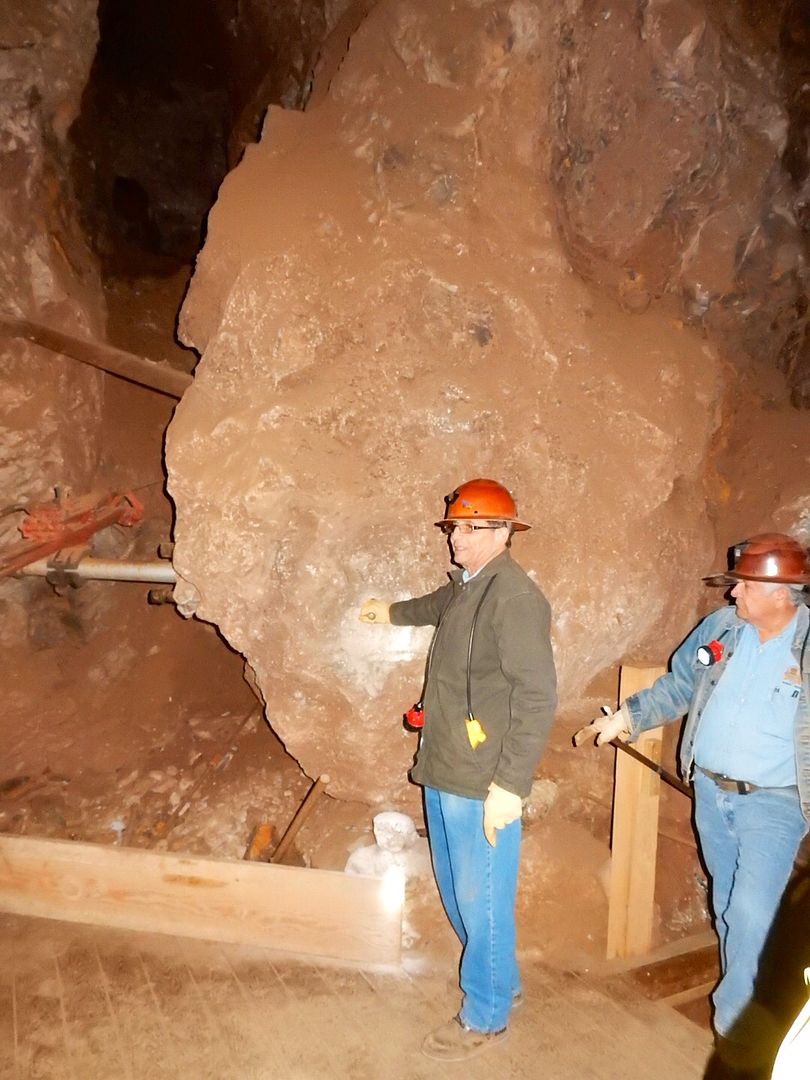

At our first stop we got off the train and climbed 36 steps to a large open area. It looked like a cave, but was instead a stope. This is an area carved out by miners leaving an open space behind. This one was created by hand (spike, sledge, explosives). More sophisticated drills were subsequently used. After one of these was created, then a specialized miner would begin drilling upward to create another stope and other miners would begin working on a horizontal tunnel leading from the area.

Our tour guide demonstrating how miners dug out ore using a bar and sledge hammer. Working in pairs, one miner would hold the bar and the other would hit it with the sledge hammer (ouch! lots of broken fingers).

When the miners created a stope, they left a portion of rock to provide support to avoid a cave in.

The second stop was at a horizontal tunnel.

This is our guide explaining the chute (above the ore bucket) where ore from levels above this one would be delivered to the this level (and then removed from the mine for processing).

Men used to push these ore buckets out of the mine. Subsequently, mules were used to haul them out. The mules could pull four, 2-ton, buckets. The mules were brought into the mines and kept there for about 3 years (stables were built underground in the mine). After that much time they would become blind. However, when the mules were returned to the surface, the vet would put a hood on them with a tiny hole for their eyes to get accustomed to the light. Over time, they would enlarge the holes in the hood and their eyesight would return.

The "boss" got tired of all of the walking that he had to do every day and this rail bicycle was built for him. The miners were constantly hiding it from him or putting rocks on the rails so he would be thrown off when cycling. He went back to walking...

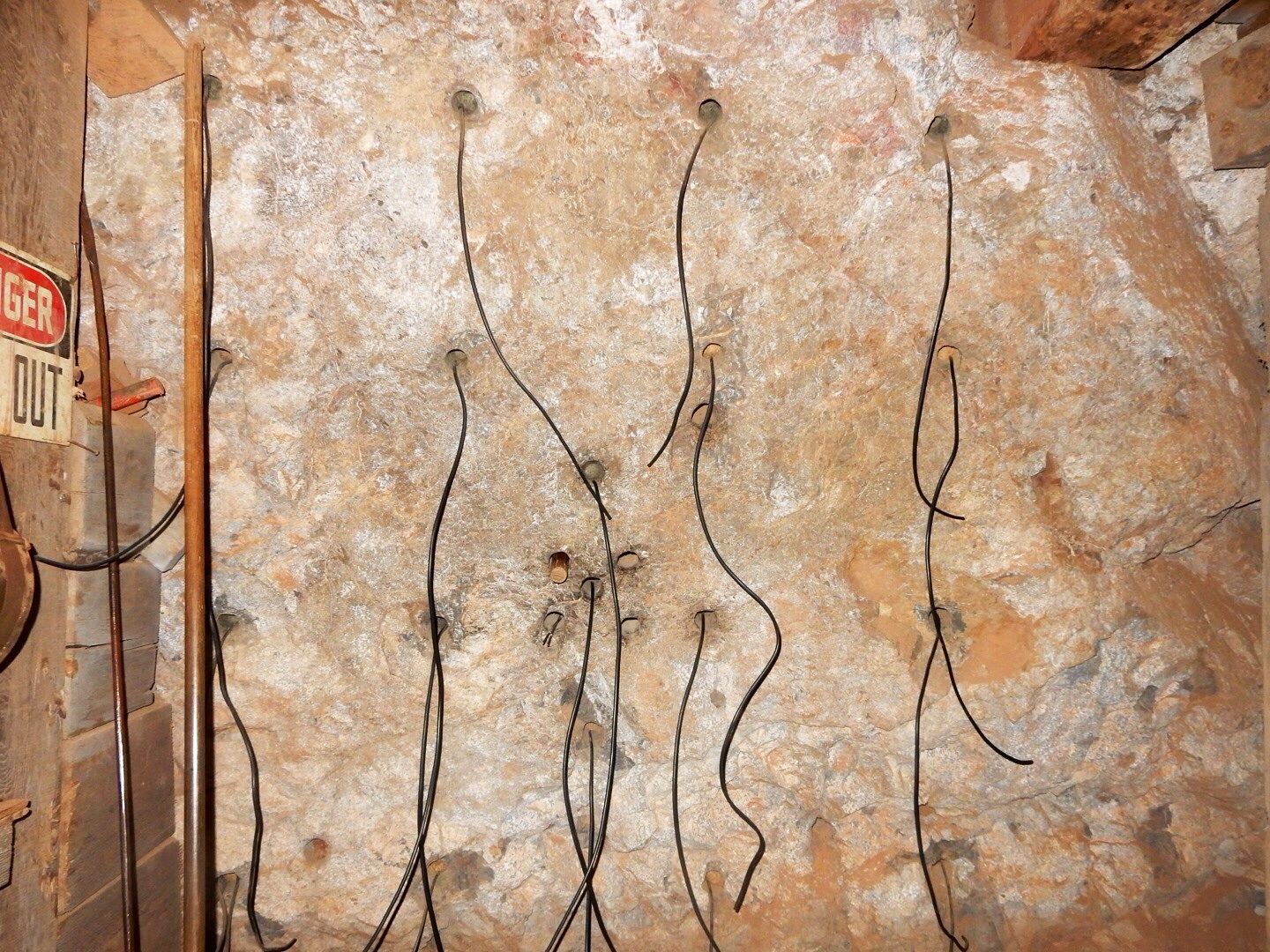

This shows the method used to blast a section of ore (8'x8'x7'). Holes were drilled in the pattern shown with fuses and dynamite. After lighting the fuse, the miners had 40 seconds to run!

Elevator shaft. This is how equipment, mules, and other items were delivered to the various levels of the mine.

Pine timber was used for structural support in the mines because if it gave way it would make noise warning the miners. If hardwood was used (like oak), it would just snap without warning. You can see this area was built in 1925 (by Joe).

Here is where the miners went to the bathroom, a nice 2-seater that was taken to the surface to be emptied on the rail system. It was called the "honey pot."

John, posing with Bill, one of our tour guides. He worked in the mines for years. We chatted with him after the tour and he provided us with information about the work and payment system. Miners were paid an hourly wage, but also could double their pay by receiving bonuses for the amount of ore they extracted or number of feet they drilled in horizontal or vertical tunnels. There were many other jobs associated with the mines, but the miners were paid the most.

A huge amount of metals valued at $6.1B (price) were mined here. Here the staggering numbers:

- 8,032,532,000 pounds of copper

- 2,871,786 ounces of gold

- 77,182,986 ounces of silver

- 304,627,600 pounds of lead

- 371,945,900 pounds of zinc

The cost of the tour is $13/adult and lasts about an hour. It was really a unique experience. Our tour guide was great and provided lots of interesting human interest stories about the miners and their lifestyle. If you visit Bisbee, don't miss this! It was great.

Website: www.queenminetour.com

No comments:

Post a Comment